Various shapes and sizes of lithium-ion batteries cater to different applications, and two contenders have been in the spotlight: prismatic and cylindrical batteries. Let’s explore these powerhouses and understand why the Prismatic Batteries might be ready to steal the show.

Prismatic Batteries: Power in a Box

Prismatic batteries come in rigid shells with a rectangular shape, allowing them to be stacked efficiently in battery modules. There are two types of prismatic batteries: stacked and flat. Stacked prismatic batteries deliver a powerful energy burst, perfect for high-performance applications. On the other hand, flat prismatic batteries focus on energy density, providing long-lasting durability. These batteries are commonly used in energy storage systems and electric vehicles due to their larger size and capacity, making them less suitable for smaller devices such as mobile phones.

Cylindrical Batteries: Compact and Versatile

Cylindrical batteries, as their name implies, come in cylindrical casings. Their compact and rounded design enables easy fitting into devices of different sizes. One of their key benefits is their ability to prevent expansion, a common problem in batteries that leads to gas buildup inside the casing. These versatile power sources initially gained recognition in laptops and have since become widely used in electric vehicles, electric bicycles, medical equipment, and space exploration. Their ability to withstand atmospheric pressure variations makes them essential for missions like those involving Mars rovers.

Key Differences between Prismatic and Cylindrical Batteries

- Size Matters: Prismatic batteries outsize their cylindrical counterparts, holding significantly more energy. To put it into perspective, a single prismatic battery can match the energy of 20 to 100 cylindrical batteries. Cylindrical batteries, being smaller in size, are suitable for applications requiring lower power and are used in a wider range of devices.

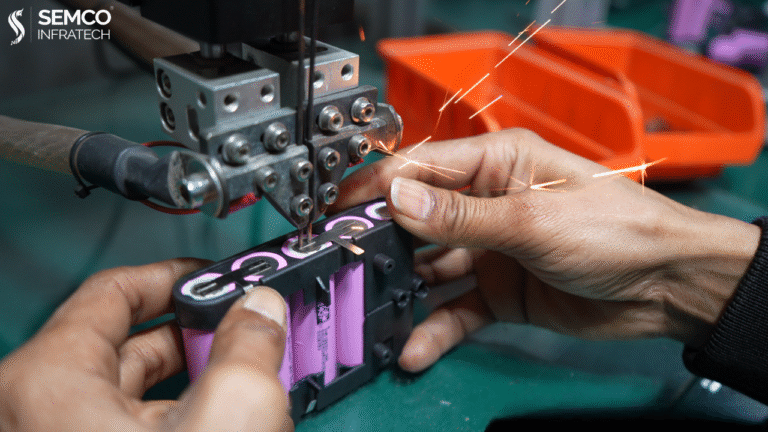

- Fewer Connections: Prismatic batteries require fewer connections due to their larger size. This means there are fewer chances for manufacturing defects, giving them a significant advantage over cylindrical batteries.

- Energy vs. Power: Although cylindrical batteries store less energy, they deliver a more powerful performance. This is because they have more connections per ampere hour (Ah). As a result, cylindrical batteries excel in high-performance applications, while prismatic batteries are great for optimizing energy efficiency.

The Prismatic Battery Revolution

The electric vehicle industry, known for its rapid evolution, poses an intriguing question: will prismatic batteries eventually surpass cylindrical ones? Currently, cylindrical batteries dominate the sector, but several factors suggest that prismatic batteries might overthrow them.

Prismatic batteries offer cost-saving opportunities by streamlining manufacturing processes. Their larger size allows for the production of bigger batteries, reducing the number of electrical connections that need welding. Furthermore, prismatic batteries are a perfect match for lithium iron phosphate (LFP) chemistry, known for its affordability and accessibility.

Unlike other chemistries, LFP batteries use easily available materials, eliminating the need for expensive rare materials like nickel and cobalt.

The rise of LFP prismatic cells is already evident, with Asian electric vehicle manufacturers adopting prismatic LFP batteries.

However, LFP chemistry has its limitations, including lower energy storage capacity, making it unsuitable for high-performance applications. Additionally, battery management systems may face challenges in accurately predicting charge levels.

Prismatic Batteries in Energy Storage Systems

The demand for battery packs goes beyond electric vehicles, with energy storage systems (ESS) playing a crucial role. Prismatic batteries are already preferred in ESS applications due to their longer cycle life, reduced risks, and lower costs compared to cylindrical batteries.

Tesla’s 4680 cylindrical cells have gained considerable attention for their compact design, high energy density, and cost efficiency. While prismatic batteries have not yet replaced them, Tesla’s future decisions could tip the scales.

Will Tesla transition to LFP chemistry and embrace prismatic batteries? The answer could have a significant impact on the battery landscape, especially with the rising global raw material costs.

The stage is set for an intriguing battle between prismatic and cylindrical batteries, and only time will reveal the winner in this electrifying competition.