Prismatic cell testing is a pivotal process in battery manufacturing and quality assurance. These specialized tests ensure prismatic cells’ performance, safety, and reliability, widely used in various applications such as electric vehicles, renewable energy storage, and consumer electronics. Prismatic cell testing involves a range of assessments, including capacity measurement, voltage analysis, impedance testing, and thermal behavior evaluation.

By subjecting prismatic cells to rigorous testing protocols, manufacturers can identify deviations from expected performance, mitigate potential issues, and deliver batteries that meet the highest standards of efficiency and durability. This introductory step is crucial in ensuring the seamless integration of prismatic cells into diverse industries, ultimately contributing to the advancement of cleaner and more efficient energy solutions.

Advantages

Prismatic cell testing offers a multitude of advantages that significantly enhance battery quality and performance. Firstly, it provides accurate and reliable insights into crucial parameters like capacity, voltage, and impedance, ensuring consistent and optimal energy storage capabilities. This meticulous testing helps identify any manufacturing defects or variations, allowing for early intervention and quality assurance. Moreover, prismatic cell testing enables the detection of potential thermal issues, ensuring safe operation even under challenging conditions.

By pinpointing weak points and discrepancies, manufacturers can fine-tune their production processes, resulting in improved overall battery design and longevity. Ultimately, prismatic cell testing guarantees that the batteries meet rigorous industry standards, delivering reliable, efficient, and safe energy solutions for a wide range of applications, from consumer electronics to electric vehicles and renewable energy systems.

Integration

The prismatic cell tester seamlessly integrates into existing battery testing processes, streamlining quality control and enhancing efficiency. Its intuitive interface and flexible configuration allow for easy incorporation into production lines, minimizing disruptions and downtime. With its compatibility across different battery types and sizes, the tester harmoniously complements the workflow, ensuring a smooth transition without major modifications.

This seamless integration empowers manufacturers to optimize their testing procedures, expedite throughput, and maintain stringent quality standards, ultimately contributing to the overall success of battery production across various industries.

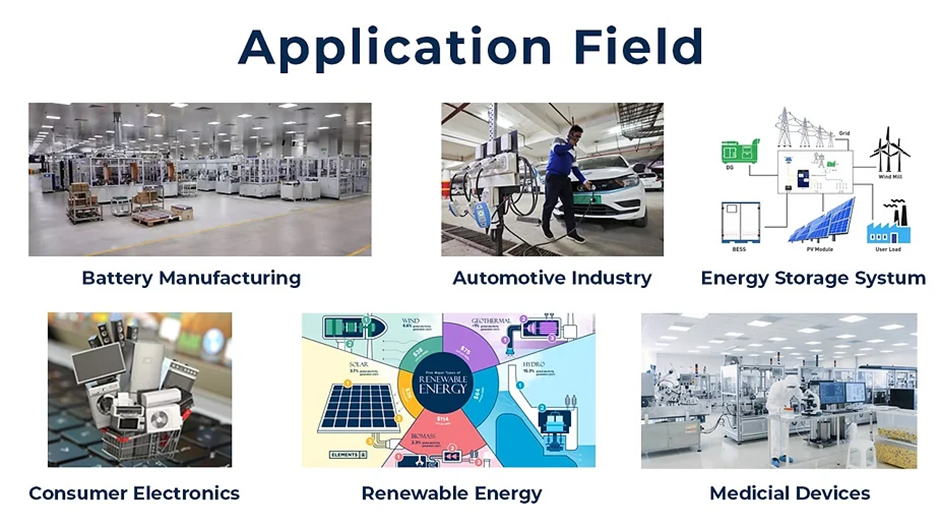

Application

Designed with precision and versatility in mind, the Semco Prismatic Cell Tester finds utility in a wide range of applications. From automotive to renewable energy and consumer electronics, our tester is engineered to enhance the quality, performance, and reliability of prismatic cells, ensuring that your battery products meet the highest industry standards.

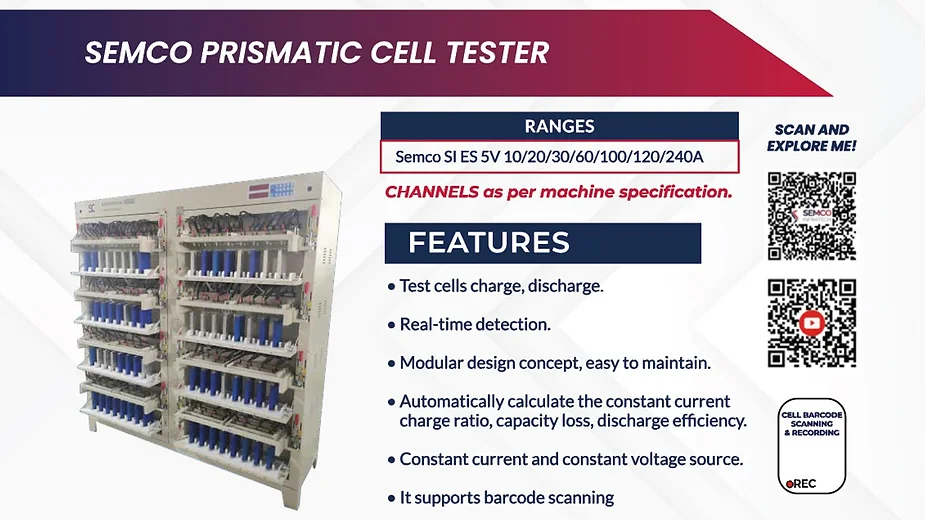

Semco Prismatic Cell Tester

Semco is one of the leaders in Lithium-ion battery testing and assembly equipment. We now not only offer but also provide professional installation services along with the availability of spares. Our inventory is full of Prismatic Cell Testers available in ranges from SI ES 5V 10/20/30/60/100/120/240A for testing prismatic cell sizes. This tester offers a range of features that can help you test the cells’ charge and discharge, real-time detection, multiple conditions for cell sorting, and automatically calculate the constant current charge ratio, capacity loss, and discharge efficiency.

Main Function

At the heart of our Prismatic Cell Tester is its ability to conduct comprehensive charge and discharge tests, partition capacity evaluations, and cycle life assessments. With configurable parameters for each channel, our tester empowers you to customize testing conditions according to your specific requirements, allowing you to gather precise data and make informed decisions.

Product Details

Experience the power of Semco’s Prismatic Cell Tester with our range of options:

- Semco 5V 30A 16CH

- Semco 5V 60A 8CH/ 64CH

- Semco 5V 120A 4CH/32CH

Specifications

- Rated Voltage: 5V

- Power Output Channels: 4 to 64 channels

Product Description

- High-precision calibration by Agilent ensures accuracy within 0.5% for charging and discharge parameters.

- Modular design for easy maintenance and scalability.

- User-friendly Human-Machine Interface (HMI) and robust software system.

- Comprehensive testing capabilities, including charge and discharge, partition capacity, cycle life, and more.

- Detachable and customizable channels to suit your specific needs.

- Data export options in Excel and TXT files for easy analysis.

- Voltage Range: 0 to 5V | Current Range: 0 to 30A (up to 300A)

- Accuracy: ±0.1% FS | Resolution: 1.0 mV

- Supports CC, CV, and CD modes.

Conclusion

With the Semco Prismatic Cell Tester, you can elevate your battery testing processes to new heights of accuracy, efficiency, and reliability. As a trusted partner in your battery manufacturing journey, Semco continues to deliver state-of-the-art solutions that drive innovation and excellence in the industry. Contact us today to learn how the Semco Prismatic Cell Tester can revolutionize your battery testing and quality assurance processes.