In modern electric vehicles (EVs), the lithium-ion battery module pack takes center stage, influencing an EV’s performance, range, and safety. However, these crucial power sources are sensitive to temperature extremes. Like people, batteries have their comfort zone, typically operating optimally between 15°C and 40°C. Yet, the reality of automotive environments exposes batteries to temperatures ranging from a frigid -20°C to a sweltering 55°C. What’s the solution? Give the battery an air conditioner, and you get battery thermal management, which accomplishes three essential functions: heat dissipation, heating, and temperature consistency.

Heat Dissipation

When temperatures soar, batteries can experience a dramatic loss of life (resulting in capacity degradation) and an elevated risk of thermal runaway. Thus, effective heat dissipation is vital when the battery becomes excessively hot.

Heating

Conversely, when temperatures plummet, the battery’s capacity may be reduced and performance weakened. Charging the battery in this frigid state can even pose a risk of thermal runaway due to potential internal short circuits. So, it’s crucial to warm up or insulate the battery when it gets too cold.

Temperature Consistency

Think back to the old air conditioner in your childhood home. It would blast cold air upon startup and then take a break. Most modern air conditioners now use frequency conversion and even airflow distribution to maintain temperature consistency. Similarly, power batteries strive to minimize spatial temperature differences, ensuring minimal variance in cell temperature. Temperature consistency is paramount to battery performance and safety.

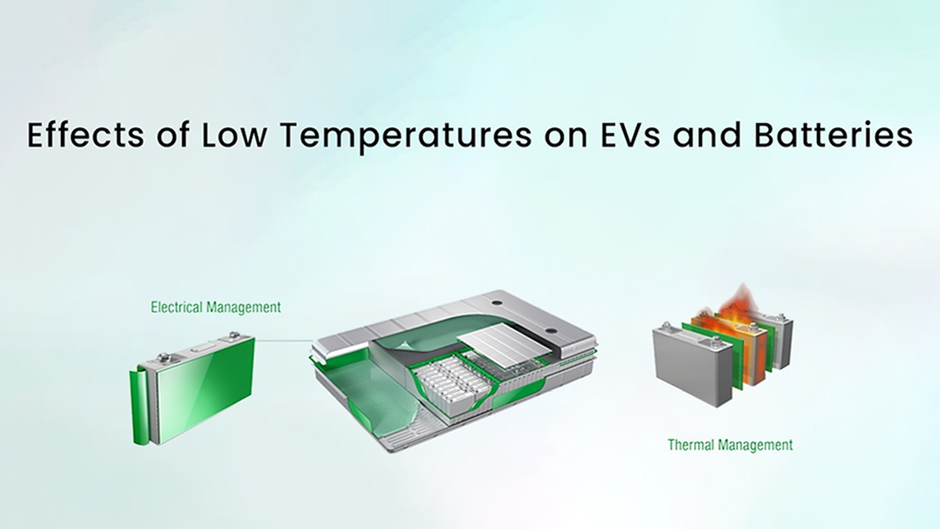

Effects of Low Temperatures on EVs and Batteries

As the heart of an EV, the power battery has a profound impact on its performance, affecting aspects such as range, acceleration, and service life. Safety is also a top priority. Battery performance is deeply intertwined with temperature, and cold climates can significantly hinder an EV’s operation.

For instance, electric vehicle owners in colder regions often notice a significant drop in mileage during winter. In some cases, the range can plummet to as low as 70% of its usual capacity. Many drivers resist using cabin heaters to conserve mileage.

Low temperatures not only reduce an EV’s battery capacity but also inhibit its discharge capabilities. At extremely low temperatures, the electrolyte inside the battery may freeze, leading to a severe reduction in power output.

Lithium-ion batteries are particularly susceptible to temperature extremes. At lower temperatures, the chemical reactions within the battery slow down, resulting in decreased performance and range. Charging in freezing conditions can also lead to the formation of lithium deposits on the battery’s negative electrode, potentially puncturing the battery diaphragm and causing a short circuit. The safety implications of charging batteries at low temperatures are significant.

Battery Thermal Management: A Technological Solution

Battery thermal management is the solution to many of these challenges. This technology aims to maintain battery temperature within the ideal range. The approach includes both heating and cooling, to optimize battery performance.

There are several methods used in battery heating:

- Battery Natural Heating: The heat generated during battery operation, discharging, or charging can increase the battery’s temperature. However, this method can be slow and is rarely used in modern electric vehicles.

- Blower Heating: Blowing hot or cold air into the battery pack through an external air conditioner is another method. This approach demands a carefully designed air duct and can result in uneven temperature distribution within the battery pack.

- Heating Elements in the Battery Pack: These are composed of heating elements and circuits. Two common heating elements are the Positive Temperature Coefficient (PTC) and Heating Film. PTC offers advantages like safety, high thermal conversion efficiency, and rapid heating.

- Circulating Liquid Heating: Liquid-cooled battery packs have become the mainstream option. This method offers uniform heat distribution, safety, and reliability. It usually features a system to facilitate heat dissipation, ensuring even temperature rises throughout the battery pack.

Conclusion

Battery thermal management is not just a luxury; it’s a necessity for modern electric vehicles. In a world of varying climates, maintaining optimal battery temperature is a key factor in enhancing performance, ensuring safety, and prolonging battery life. As technology continues to evolve, battery thermal management will continue to play a crucial role in advancing the electric vehicle industry, offering the promise of efficient and reliable clean energy transportation for the future.