Are you someone looking for lithium-ion battery-making equipment for a new plant? Do you have things in your mind cluttered with ideas that lack execution? The problem starts when someone plans to make a battery assembly plant but doesn’t know where to buy the equipment. Therefore, we have tried to find the best information about choosing the best equipment for your needs. We will also look at the factors you must consider when selecting machines.

Choosing What You Need

Understanding your production needs is one of the most important parts affecting budget, performance, and efficiency. Before asking anyone else, find answers to some questions. What are the requirements of your plant, what type of battery are you making, and who are the right customers for the products? If you are someone who just wants to produce a few batteries for the research and development process, lab-sized equipment would be best for you. You can contact any of the lithium-ion battery manufacturing equipment suppliers and ask them about the machines as per your requirements. Semco Infratech is also one such supplier holding a legacy of more than two decades.

Additionally, you must know the current and future production capacity and requirements of your plant. You should know which cell type are you going for. What would be the application of the battery you are making? You must also consider the size and scale of your operations

Factors to Consider for Battery-Making Equipment

- Automation and Efficiency

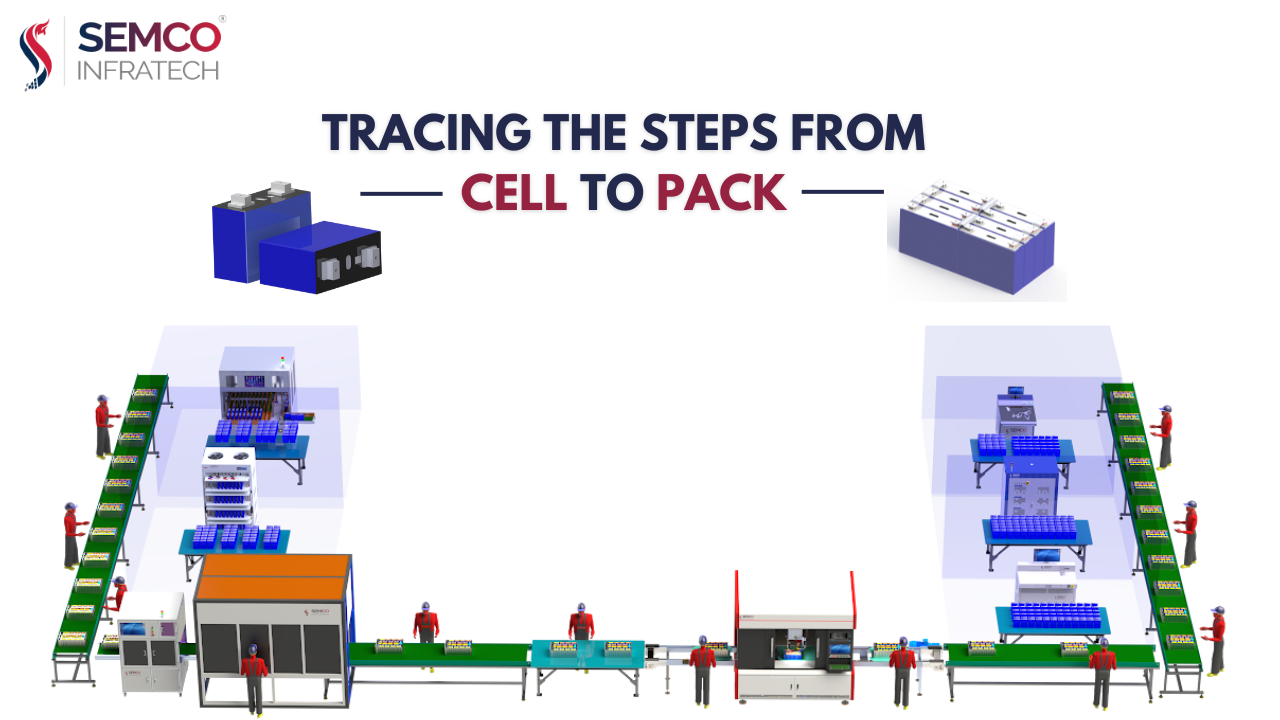

Every battery production line consists of machines and generally a conveyor to make and transport batteries from one place to another. Battery assembly lines are of two types: one is automotive and the other is manual. An automatic lithium-ion battery assembly line does processes like cell feeding and welding through robotic arms while a manual line doesn’t have such features. Manual machines are less efficient when compared to automatic ones. Equipment for lithium battery assembly with high levels of automation to improve efficiency and reduce labor costs. They increase the productivity and speed of the production.

- Quality and Precision

When you’re looking for lithium-ion battery production equipment, it’s super important to go for machines that guarantee consistent quality and precision. Think about ones with advanced quality control features—they can monitor everything in real time and make automatic adjustments. This way, you get batteries that meet high standards and have fewer defects. If the products work well for a long time, the brand image would be very good resulting you more customers.

- Flexibility and Adaptability

Choose equipment that is customizable or at least supports multiple types and sizes of battery. It’s all about being able to adapt quickly to market changes without too much hassle. equipment for lithium battery assembly that is easy to adjust and reconfigure will save you time and money in the long run, they’ll keep your production line versatile and ready for new challenges.

- Reliability and Durability

Going for equipment from well-known manufacturers who have a solid track record is a smart move. If you go with a non-reputed brand, there is a risk of getting inferior-quality machines. There can be situations in which you end up haltering the production just because of those machines. Look for machines that are built tough and don’t need a lot of maintenance. Semco Infratech provides reliable and durable equipment that has almost no breakdowns. Semco battery testing machines mean less downtime, so your production stays on track and you don’t end up spending a fortune on repairs.

- Cost and Return on Investment (ROI)

When you’re buying equipment, it’s not just about the initial price tag—you need to think about the long-term operation costs too. Calculate the potential ROI by considering your production goals and market forecasts. This way, you can make sure that the investment is worth it and that it’ll pay off over time, helping you stay profitable and competitive.

Sourcing and Purchasing Battery-Making Equipment

If you have answers to all the questions mentioned above, you are good to go for your lithium-ion battery production equipment. You must also research and compare different manufacturers and suppliers. Semco Infratech is a company for all those who do not want to test and try every lithium-ion battery assembly equipment provided. We have the availability of spare parts and technical support and we provide times delivery and installation for all the machines.

Conclusion

When choosing battery-making equipment, know your exact needs – production capacity, battery type, and target customers. Look for automated, efficient machines that guarantee quality and precision. Opt for flexible, adaptable, and durable equipment for lithium battery assembly to future-proof your operations. And consider the long-term costs and return on investment. Doing thorough research and finding a reputable supplier like Semco Infratech can set you up for success. The right equipment choices will boost your productivity, quality, and profitability.