Lithium-ion batteries are the unsung heroes of our tech-savvy world. These powerhouses come in various shapes, sizes, and configurations and employ the magic of lithium to store and release energy. This article will explore the classification, working principle, and structural components that make these batteries tick.

1. Classification of Lithium-Ion Batteries

Lithium batteries are classified based on usage, energy characteristics, and power delivery capabilities. Three main categories emerge:

- Energy-Type Lithium Batteries: These are designed for the long haul. They’re great at storing energy over extended periods, making them ideal for applications like laptops, cameras, and other electronic devices that require a steady, reliable power source.

- Power-Type Lithium Batteries: When you need a burst of energy, power-type lithium batteries step up to the plate. These batteries can deliver high current, making them a perfect choice for devices like power tools or electric vehicles that require sudden, intense bursts of energy.

- Fast-Charging Lithium Batteries: As the name suggests, these batteries are all about speed. They can absorb and deliver energy quickly, which is why they’re popular in the fast-charging devices we use daily, from smartphones to electric scooters.

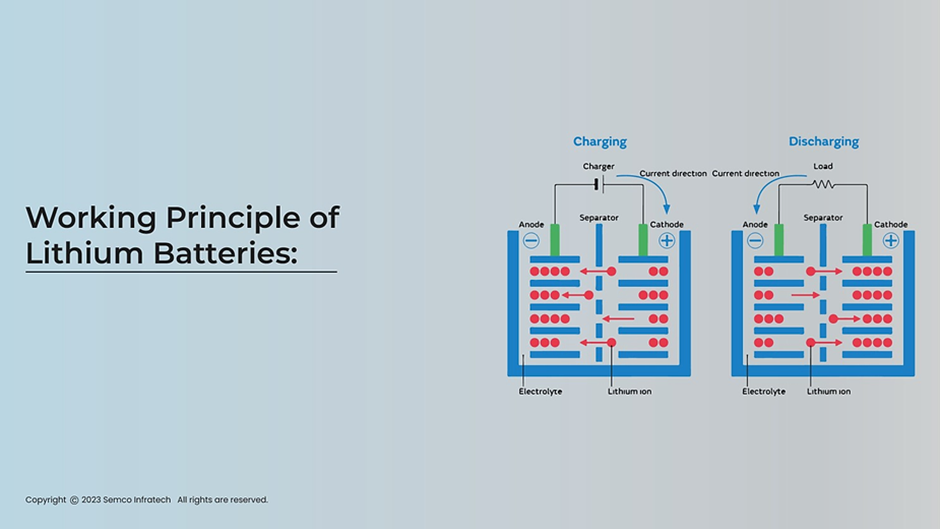

2. Working Principle of Lithium Batteries

At the heart of a lithium-ion battery lies a fundamental electrochemical process. The essence of this process is the transformation of lithium from one form to another and the simultaneous transfer of lithium ions and electrons, resulting in the conversion of electrical energy to chemical energy and vice versa.

- Charging Phase: When you plug in your device to charge, you’re converting electrical energy into chemical energy. Lithium ions migrate from the positive electrode through a separator to the negative electrode, and electrons flow through the external circuit. When they meet at the negative electrode, lithium ions are embedded into the electrode material, storing energy.

- Discharging Phase: When you unplug your device and start using it, the chemical energy stored in the battery is converted back into electrical energy. Lithium ions are released from the negative electrode, travel through the separator to the positive electrode, and electrons once again flow through the external circuit. At the positive electrode, electrons and lithium ions combine with stable positive electrode materials, generating the electricity needed to power your device.

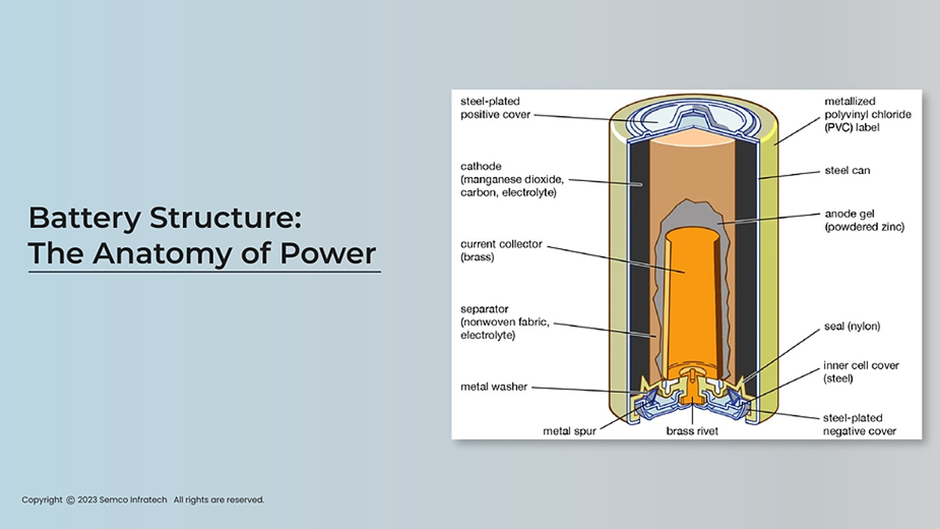

3. Battery Structure: The Anatomy of Power

Lithium batteries are a complex interplay of several components, each playing a crucial role in their performance. Let’s break down the structure:

- Positive Electrode (Cathode): The positive electrode is typically coated with a lithium-containing alkali salt, providing the battery with a source of lithium. The positive electrode material also determines the battery’s capacity, making it a central component.

- Positive Electrode Tab (Ear): This structure bridges the positive electrode sheet and the external circuit. Its design significantly influences the battery’s overcurrent capacity.

- Ceramic Coating: Often applied to the positive electrode side, ceramic coatings, usually alumina, serve several functions. They help prevent burrs during manufacturing, reduce the risk of misalignment, and enhance laser absorption during the cutting process.

- Current Collector (Foil): The positive electrode’s current collector is primarily composed of aluminum foil. It provides an attachment point for the positive electrode coating and acts as a carrier for overcurrent.

- Negative Electrode (Anode): The negative electrode contains carbon-based materials and provides the sites for lithium embedding within the battery. This material determines the battery’s capacity.

- Negative Electrode Tab (Ear): Similar to its positive counterpart, the negative electrode tab bridges the negative electrode and the external circuit and significantly affects the battery’s overcurrent capacity.

- Current Collector (Foil): In the negative electrode, copper foil is often used for the current collector. Like its positive counterpart, it offers an attachment point for the negative electrode coating and functions as an overcurrent carrier.

4. Battery Arrangements: Series and Parallel Connections

Lithium batteries can be combined in series or parallel configurations to achieve specific voltage and capacity requirements. When connected in series, the battery voltages are additive, creating higher voltages. In a parallel configuration, the capacities are additive, yielding longer battery life.

Conclusion

As we unravel the intricacies of lithium-ion batteries, from their diverse classifications to the fundamental electrochemical processes at play, a profound understanding emerges of the silent workhorses powering our digital age. The structure, with its positive and negative electrodes, intricate tabs, and specialized coatings, becomes a testament to the meticulous engineering behind these energy storage marvels.

The arrangement of batteries in series or parallel configurations further underscores their adaptability to diverse voltage and capacity requirements. In conclusion, the journey through the world of lithium batteries unveils not just the technical brilliance that enables our devices but also the potential for continued innovation in energy storage, pointing toward a future where these unassuming powerhouses play an even more integral role in our evolving technological landscape.