The rise of lithium-ion batteries in various applications—from electric vehicles to consumer electronics—has increased the demand for precise and efficient sorting systems. Among the critical components in battery production, the prismatic cell sorting machine plays a pivotal role in ensuring performance, safety, and reliability.

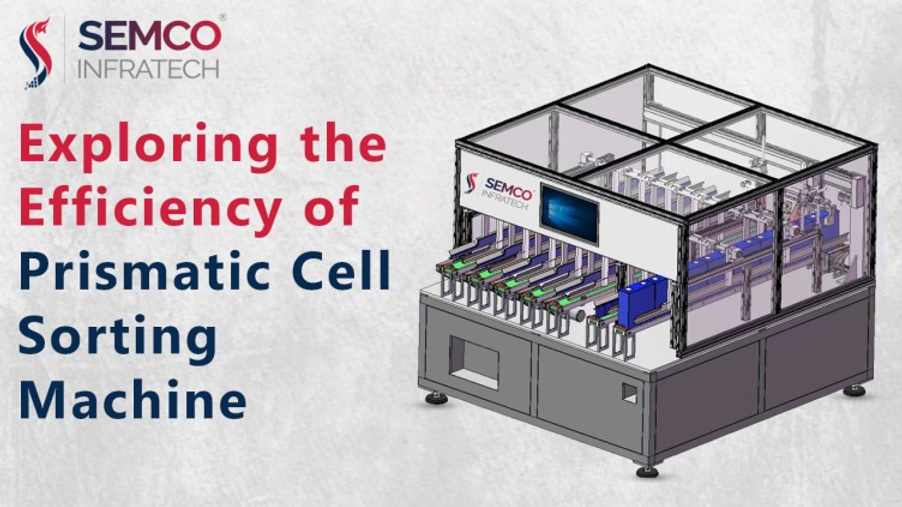

What is a Prismatic Cell Sorting Machine?

A prismatic cell sorting machine is a specialized piece of equipment designed to classify and sort prismatic lithium-ion cells based on specific parameters such as voltage, internal resistance, and capacity. This automated process helps manufacturers ensure that only cells meeting stringent quality standards are used in assembling battery packs.

How Does It Work?

The operation of a prismatic cell sorting machine typically involves:

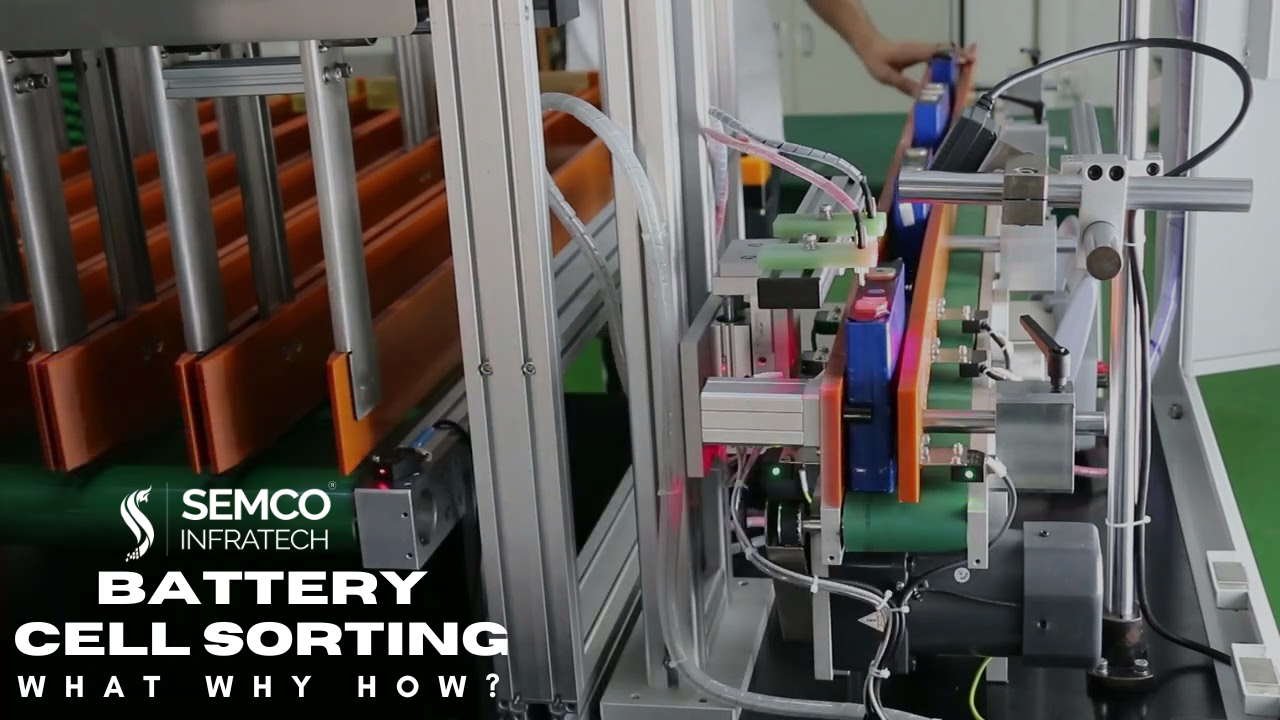

- Cell Feeding: Cells are loaded into the machine either manually or via automated feeding systems.

- Measurement: Advanced sensors and testing modules measure critical parameters such as Open Circuit Voltage (OCV) and Internal Resistance (IR).

- Classification: Based on predefined thresholds, the machine categorizes the cells into different bins or groups for further processing.

- Data Recording: Every sorted cell’s data is logged into a database for traceability and quality control.

Key Benefits of Using a Prismatic Cell Sorting Machine

- Enhanced Accuracy: The high-precision sensors in these machines ensure that only cells with optimal performance metrics are selected.

- Improved Efficiency: By automating the sorting process, manufacturers can process thousands of cells daily, significantly reducing labor costs and errors.

- Quality Assurance: Sorting ensures consistency in battery pack performance, which is critical for applications like electric vehicles and energy storage systems.

- Reduced Waste: Proper classification minimizes the risk of defective cells being assembled, reducing wastage and enhancing sustainability.

Applications of Prismatic Cell Sorting Machines

- Electric Vehicles (EVs): Ensuring uniformity in battery packs to meet the high energy and performance demands of EVs.

- Energy Storage Systems (ESS): Guaranteeing reliability in storage systems for renewable energy solutions.

- Consumer Electronics: Providing consistent power for high-performance gadgets like smartphones and laptops.

Features to Look for in a Prismatic Cell Sorting Machine

When selecting a prismatic cell sorting machine, consider the following features:

- Multi-Parameter Testing: Ability to measure OCV, IR, and capacity.

- High Throughput: Capability to process a large number of cells efficiently.

- Data Integration: Options for real-time data recording and integration with Manufacturing Execution Systems (MES).

- Compact Design: Space-efficient machines that fit seamlessly into production lines.

- Customizable Settings: Flexibility to adjust parameters based on specific requirements.

Conclusion

The prismatic cell sorting machine is a game-changer in lithium-ion battery manufacturing, offering unparalleled efficiency, accuracy, and quality assurance. As the demand for advanced batteries continues to grow, investing in cutting-edge sorting technology becomes essential for manufacturers aiming to stay competitive in the market.

By integrating a prismatic cell sorting machine into production processes, companies can enhance their operational efficiency, ensure product reliability, and contribute to a more sustainable future.