Lithium-ion batteries have become an essential part of our lives, powering our smartphones, laptops, electric vehicles, and even our homes. However, as we continue to rely on these batteries, their performance gradually degrades, leading to reduced efficiency and shorter lifespan. To address this issue, researchers have developed a revolutionary laser cleaning technology that can enhance the performance and longevity of lithium-ion batteries.

Laser Cleaning Technology

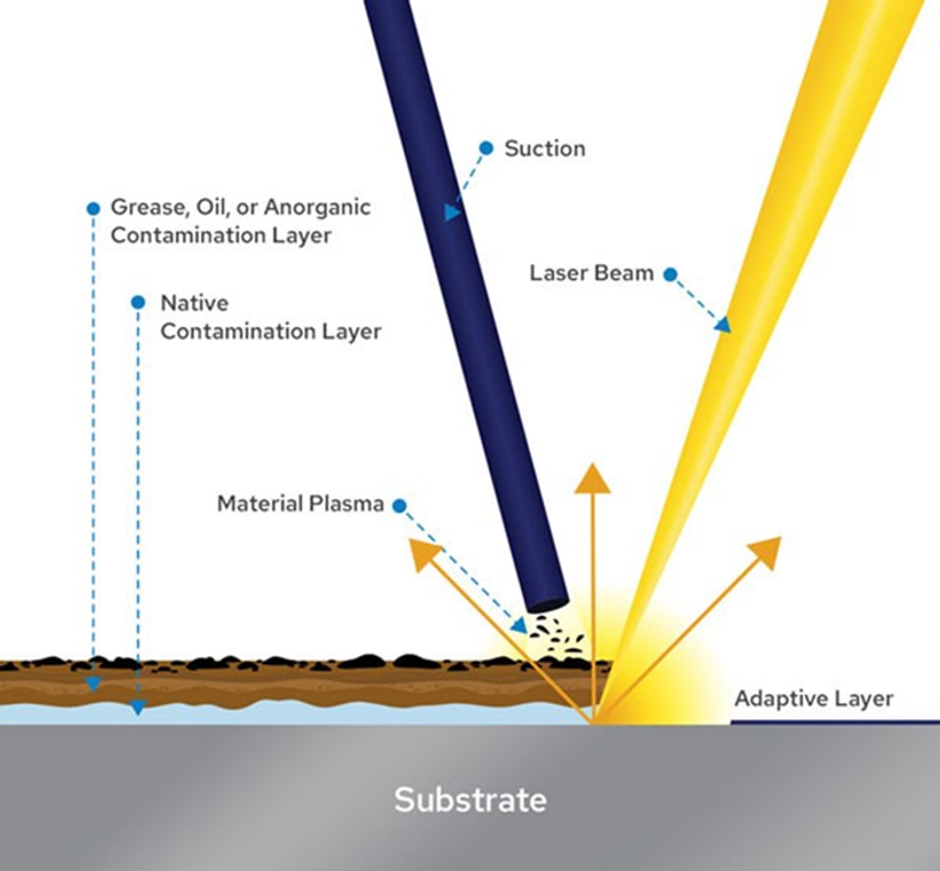

Laser cleaning technology is a non-contact cleaning method that uses high-energy laser beams to remove contaminants from surfaces. It is a highly precise and efficient cleaning technique that can remove even the tiniest impurities without damaging the underlying material. Laser cleaning technology has been used in various industries, including automotive, aerospace, and electronics manufacturing.

Laser Cleaning Technology for Lithium-Ion Batteries

Lithium-ion batteries contain electrodes that are coated with various materials, including graphite, silicon, and metal oxides. Over time, these materials can degrade and form a thin layer of solid electrolyte interface (SEI) on the electrode surface. This layer can reduce the battery’s performance by increasing its internal resistance and reducing its capacity.

Laser cleaning technology can remove the SEI layer from the electrode surface without damaging the underlying material. The laser beam heats the SEI layer, causing it to evaporate and leaving behind a clean surface. This process can restore the battery’s performance and increase its lifespan.

Applications of Laser Cleaning Technology for Lithium-Ion Batteries

Electric Vehicles

Electric vehicles (EVs) are becoming increasingly popular as a sustainable alternative to traditional gasoline-powered cars. However, one of the major challenges of EVs is their limited driving range. Laser cleaning technology can improve the performance of lithium-ion batteries used in EVs by removing the SEI layer and increasing their capacity. This can extend the driving range of EVs and make them more practical for long-distance travel.

Energy Storage Systems

Energy storage systems (ESS) store renewable energy generated from sources such as solar and wind power. However, the performance of ESS can degrade over time due to the formation of the SEI layer on the battery electrodes. Laser cleaning technology can restore the performance of ESS by removing the SEI layer and increasing its capacity. This can improve the reliability and efficiency of renewable energy systems.

Consumer Electronics

Lithium-ion batteries are used in various consumer electronics, including smartphones, laptops, and tablets. Due to battery aging, the performance of these devices can degrade over time. Laser cleaning technology can restore the performance of lithium-ion batteries in consumer electronics by removing the SEI layer and increasing their capacity. This can extend the lifespan of these devices and reduce electronic waste.

Semco Laser Cleaning Machine

We are excited to present to you our latest innovation – Semco Laser Cleaning Machines. As a frontrunner in advanced manufacturing solutions, Semco continues to push the boundaries of technological excellence. Our Laser Cleaning Machines offer a transformative approach to industrial cleaning, providing unparalleled efficiency, precision, and sustainability.

Unveiling the Power of Laser Cleaning

Laser cleaning has emerged as a game-changer in industrial cleaning processes. With Semco’s Laser Cleaning Machines, the conventional methods of abrasive cleaning, chemical cleaning, and manual labor are now things of the past. Our machines employ high-intensity laser beams to remove rust, paint, coatings, contaminants, and debris from various surfaces, leaving them impeccably clean without any damage or residue.

Versatility Redefined

Semco Laser Cleaning Machines are engineered to tackle a diverse range of cleaning challenges. From automotive parts and machinery maintenance to electronics manufacturing, our machines deliver consistent and reliable results on different surfaces, materials, and complexities. With adjustable laser parameters, our machines adapt to your specific cleaning needs.

Precision and Safety Guaranteed

Achieving precision cleaning without harming the underlying substrate is paramount, and our Laser Cleaning Machines excel in this aspect. The non-contact cleaning process ensures that delicate components, intricate patterns, and sensitive materials remain intact. Moreover, the process is environmentally friendly, eliminating the need for harsh chemicals and reducing waste.

Enhanced Efficiency and Cost Savings

Laser cleaning drastically reduces downtime and labor costs associated with traditional cleaning methods. Our machines require minimal maintenance, and their high-speed operation ensures rapid cleaning, optimizing productivity and resource utilization. As a result, you experience substantial cost savings while maintaining impeccable cleanliness.

Embracing Sustainability

At Semco, sustainability is at the heart of our innovations. Laser cleaning reduces the consumption of water, chemicals, and energy, making it an eco-friendly choice for industrial cleaning. By minimizing waste generation and promoting resource efficiency, our Laser Cleaning Machines contribute to your company’s green initiatives.

Laser Cleaning Machine Series Comparison with Traditional Cleaning

Conclusion

Laser cleaning technology is a revolutionary method for enhancing the performance and longevity of lithium-ion batteries. It offers a non-contact, precise, and efficient way to remove contaminants from battery electrodes without damaging the underlying material. The potential applications of this technology are vast, ranging from electric vehicles to consumer electronics. As we continue to rely on lithium-ion batteries for our daily needs, laser cleaning technology offers a promising solution for improving their performance and reducing environmental impact.