As the electric vehicle market grows, demands for high-quality batteries become more critical. A battery is the heart of an EV; its performance, range, and safety features are directly related to it. Quality and reliability are crucial, which is where battery testing comes into play. In this blog, we look into how battery testing affects the quality standard in EV manufacturing, including what an EV battery assembly line is, what the role of Battery Testing Equipment for EVs might be, and what Lithium-Ion Battery Testing for EVs entails.

The Role of Battery Testing in EV Manufacturing

Battery testing is just a part of testing the whole manufacturing process for EVs and ensures that the batteries completely meet the required quality and safety standards. With the emerging trends of EVs, producers face huge pressure to produce batteries that are not only of high performance but also safe and reliable. Testing allows the manufacturer to identify defects or low-performance capacity before installing the batteries in vehicles, reducing the chances of field failures.

EV Battery Assembly Importance

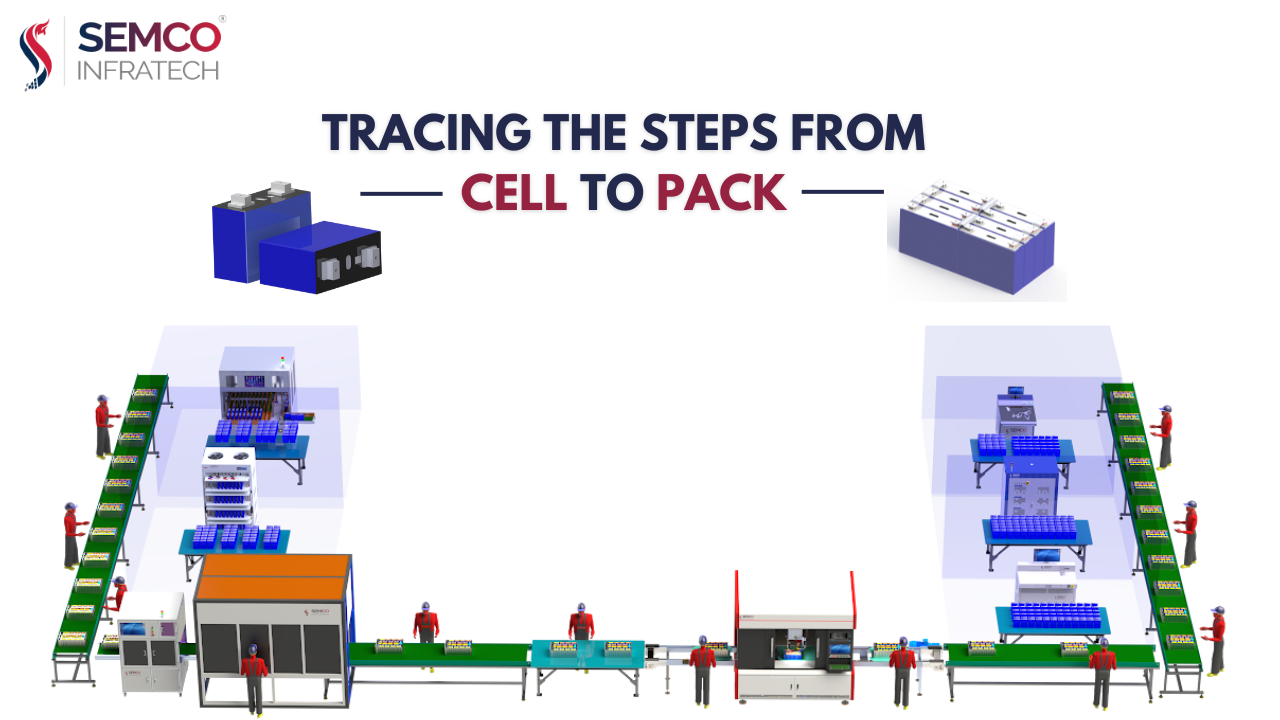

The place where the battery cells will be going into modules and packs is the EV battery assembly line. Each phase of the assembly must go through stringent quality checks for the final product to come out to specifications. A well-organized assembly line incorporates testing at various stages: from incoming cell testing, through module testing to final Battery Pack Testing for an EV. By this means, integrating such tests into an assembly line ensures that defective units are caught on time to ensure quality across units.

Battery Testing Equipment for EVs: The Backbone of Quality Assurance

Invest in the right Battery Testing Equipment for EVs to ensure only quality EVs leave the production line. Testing equipment and technologies will be designed to test capacity, charge/discharge rates, thermal stability, and safety under various conditions. Advanced testing equipment with an enriched set of features will ensure that each pack will meet the needed performance and safety requirements, building trust among consumers in EV technology.

Lithium-Ion Battery Testing for EVs: Making Sure Safety and Performance

Lithium-ion battery testing of EVs is an increasingly important process that more and more manufacturers are considering since the adoption of this technology is increasing in the industry as a result of its high energy density and efficiency. However, lithium-ion batteries are equally prone to thermal runaway and other safety issues in case they are not tested and handled properly. Their testing incorporates a set of intensive tests, which range from mechanical and electrical to thermal. Due to this thorough testing, manufacturers ensure that batteries will operate in various conditions and minimize the possibility of failures that could result in costly recalls or even safety hazards.

EV Battery Pack Testing: Quality’s Last Check

Once the individual cells and modules are built into a complete battery pack, the last step for EVs to ensure that the entire system works as specified is Battery Pack Testing for EVs. It will include a wide variety of tests: electrical integrity, thermal management, and overall system performance under various load conditions. The goal of this test campaign is to confirm that the battery pack performs as expected without any compromise on safety.

Conclusion

Battery testing is not only a part of manufacturing processes but also an extremely important factor in determining the quality and safety of electric vehicles. The manufacturer can ensure the highest quality standards for his batteries by introducing strict testing protocols right from the EV battery assembly line up to the final Battery Pack Testing for EVs. Advanced battery testing equipment for EVs and comprehensive Lithium-Ion Battery Testing for EVs play an important role in the construction of safer, more reliable electric vehicles that consumers believe in. Moving forward, continuing these high standards will be the epitome of sustaining growth and innovation in this industry.