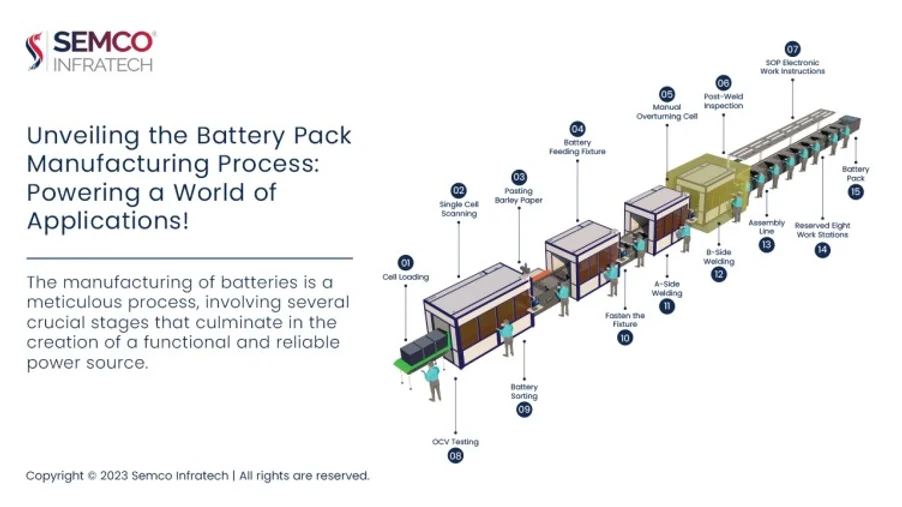

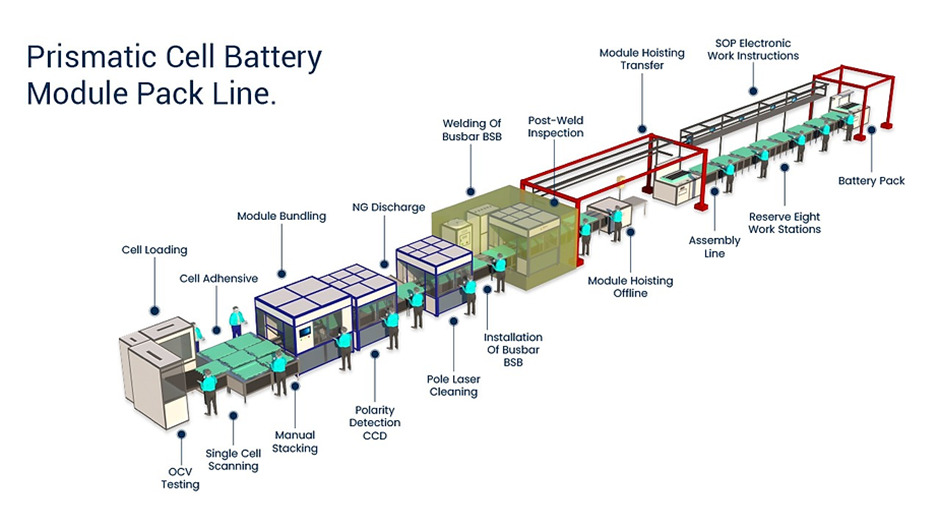

The journey of a battery’s transformation from a collection of individual cells to a powerful energy source involves several intricate steps. In this article, we focus on the final piece of this puzzle—the battery pack assembly process. In this process, the individual battery cells are ingeniously crafted into modules and eventually form a complete battery pack. Let’s dive into the fascinating world of battery pack assembly line and see how this vital step is achieved.

Connecting Battery Cells: The First Step

The initial stage of battery pack assembly begins with the careful connection of battery cells. Each battery cell’s surface is meticulously cleaned to ensure a pristine connection. This connection process involves linking battery cells and creating a structured arrangement. The configuration of these cells and the number of modules can vary significantly, depending on the specific application and battery model.

Battery cells are like the building blocks of energy storage. Their ability to store electrical energy makes them the core of the battery assembly process. Connecting them correctly is paramount in achieving the desired electrical performance.

Modularization: A Framework for Battery Pack Assembly

With the individual battery cells connected, the next step is modularization. In this phase, the connected battery cells are securely fastened into a module case. This module case typically comes with an adhesive coating to ensure a robust bond.

To create modules, electrical connections between the connected battery cells must be established. Depending on the specific design and requirements of the battery pack, this can be achieved through either a wiring harness or a busbar. After the electrical connections are made, the module is sealed with a cover, giving it its final structure. The number of modules created during this phase can vary depending on the application and battery model. These modules are like the building blocks of the battery pack, and each module forms an essential part of the larger energy storage system.

Component Assembly: The Key to Completing the Puzzle

The assembly process progresses as multiple modules are brought together to create a complete battery pack. These modules are carefully interconnected, ensuring that the electrical connections are secure, and the modules are correctly aligned. This intricate interconnection creates a cohesive unit, ready to provide power for a wide range of applications.

Each battery pack can be tailored to specific needs by adjusting the number of batteries and modules it contains. This customization is a remarkable aspect of battery pack assembly, as it allows manufacturers to create energy solutions that suit diverse applications, from electric vehicles to renewable energy systems.

The Vital Role of Battery Management Systems (BMS)

Once the battery pack is assembled, a crucial step remains – the application of the Battery Management System (BMS). The BMS plays a pivotal role in monitoring and managing the battery’s health and performance. This system provides valuable insights into the battery’s charging status and its expected service life.

A key component of the BMS is the Battery Monitoring Unit (CMU), which evaluates and balances the state of the battery cells. This balancing ensures that all cells in the battery pack are operating optimally, safeguarding their longevity and efficiency. The BMS offers real-time data, ensuring the battery remains in the best possible condition.

The application of BMS is a testament to the commitment to safety, performance, and longevity in battery manufacturing. It’s a technology that helps optimize the use of energy storage solutions sustainably and efficiently.

Conclusion: Creating Power, One Module at a Time

The battery pack assembly process is a remarkable journey, where individual battery cells evolve into powerful energy solutions. This process highlights the importance of precision, customization, and the integration of cutting-edge technology. Battery packs assembled with care and expertise find applications in electric vehicles, consumer electronics, renewable energy systems, medical devices, and more.

As the world continues to transition towards cleaner, more sustainable energy solutions, the role of battery pack assembly grows in significance. With advancements in technology and research, we can expect battery packs to continue shaping a greener, brighter future for generations to come.

So, the next time you pick up your smartphone, drive an electric vehicle or enjoy the benefits of renewable energy, remember the meticulous craftsmanship that went into the creation of the battery pack, transforming it from individual cells into a powerful source of energy. It’s a testament to human innovation and our commitment to a sustainable future.