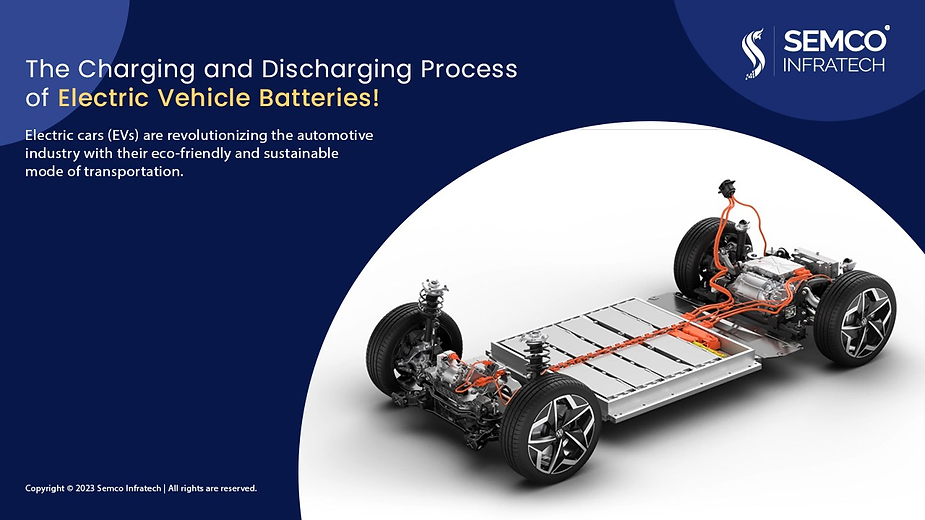

Electric cars (EVs) are revolutionizing the automotive industry with their eco-friendly and sustainable mode of transportation. The key to EVs is their power batteries, which undergo a complex yet crucial charging and discharging process.

Understanding these processes is crucial to grasping how EVs efficiently store and use electrical energy. This article will explore the intricate workings of the charging and discharging processes that drive the electric revolution.

Charging Process:-

- Power Connection: To begin the charging process, the electric vehicle is linked to a power source, usually a charging pile or a charging station. These charging points supply the required current and voltage to transfer electrical energy to the vehicle’s battery pack.

- Battery Management System (BMS) Control: The Battery Management System (BMS) plays a crucial role throughout the charging process. It closely monitors and controls different battery parameters like voltage, temperature, and current. The main goal of the BMS is to safely charge the battery within set limits, preventing overcharging and overheating.

- Charging Process: When the vehicle links to the power source, a chemical reaction starts inside the battery. Electrons move from the negative electrode to the positive electrode, and lithium ions travel from the positive electrode to the negative electrode. This complex redox reaction efficiently converts electrical energy into chemical energy, storing it within the battery.

- Charging Rate: The charging rate differs based on the battery’s design and the capabilities of the power supply. Fast-charging systems can provide a significant amount of power in a short period, with some reaching an 80 percent charge in just 30 minutes. However, it’s crucial to carefully handle the charging process to avoid overheating, as this can negatively impact battery health.

Discharge Process:-

- Electric Drive Requirements: When the electric vehicle is ready to operate or perform other tasks, the Battery Management System (BMS) takes control. The BMS determines the suitable discharge rate based on the vehicle’s operational requirements.

- Discharge Process: During the discharge process, the battery’s chemical reactions undergo a reversal. Lithium ions migrate from the negative electrode to the positive electrode, while electrons travel from the negative electrode to the positive electrode. This electron movement generates an electric current, which powers the electric motor responsible for propelling the vehicle.

- Battery Condition Monitoring: To maintain battery health and performance, constant attention is necessary. The BMS continually observes the battery’s status, ensuring cell balance, and stable voltage, and preventing over-discharge. These steps are crucial for prolonging the battery’s lifespan and preserving its abilities.

- Energy Release: The primary result of the discharge process is the release of electrical energy to operate the electric vehicle. The discharge rate is determined by the vehicle’s acceleration and power requirements, along with the battery’s design.

Conclusion

The charging and discharging processes are the vital components of power batteries in electric vehicles. They enable the storage and conversion of electrical energy, offering a sustainable power solution for the EV revolution.

Amidst this intricate journey, the Battery Management System (BMS) serves as the protector of safety, stability, and efficiency, ensuring the battery operates securely and efficiently. As the electric vehicle industry progresses, a deeper comprehension of these processes will undoubtedly propel further advancements in EV technology, promising a greener and more sustainable future for transportation.