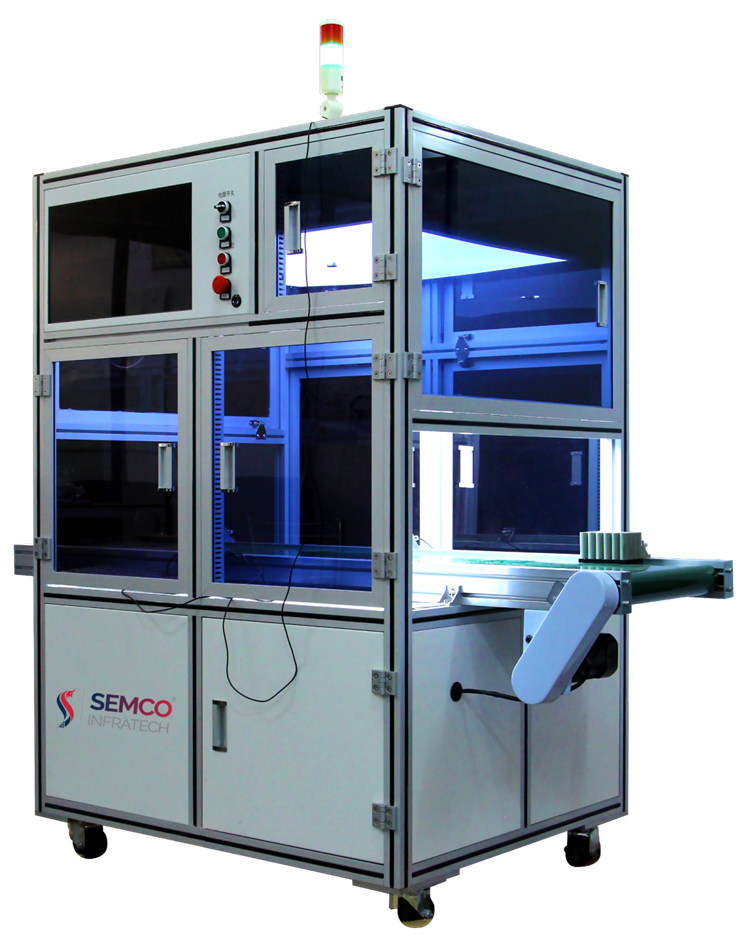

In battery manufacturing, ensuring correct polarity is critical for safety, efficiency, and product reliability. The CCD Polarity Tester Machine is an advanced vision-based system designed to verify the polarity of battery cells, modules, or packs before they proceed to the next stage of production. By using Charge-Coupled Device (CCD) cameras and image processing technology, this machine detects incorrect battery orientations, preventing assembly errors that could lead to electrical failures, reduced efficiency, or hazardous situations.

This article explores the working mechanism and significance of CCD Polarity Tester Machines in the battery industry, particularly in EV battery manufacturing, consumer electronics, and energy storage systems.

How a CCD Polarity Tester Machine Works?

1. Battery Placement

- The battery cell or module is positioned in the testing station.

- This can be done manually or through an automated conveyor system for high-speed manufacturing lines.

2. Image Capture Using CCD Camera

- A high-resolution CCD camera captures detailed images of the battery’s terminals.

- The camera is positioned to get a clear view of polarity indicators, such as symbols, colors, or terminal shapes.

3. Polarity Verification Process

- The captured image is processed using machine vision algorithms.

- The system compares the terminal orientation with predefined polarity templates stored in its database.

- If the polarity matches the expected orientation, the battery is marked as passed.

- If the polarity is incorrect, the system flags the battery as rejected.

4. Sorting and Classification

- Pass Batteries: Batteries with the correct polarity move forward in the production process.

- Reject Batteries: Batteries with incorrect polarity are flagged for correction or removal.

- Some systems integrate robotic handling to automatically sort out non-compliant batteries.

Mechanism Behind CCD Polarity Testing

1. Charge-Coupled Device (CCD) Camera Technology

- The CCD camera captures high-resolution images of battery terminals.

- It offers superior light sensitivity, ensuring clear image detection in varying lighting conditions.

2. Image Processing Software

- The system processes images in real time using pattern recognition and AI-based algorithms.

- It identifies terminal markings, color codes, or shapes to verify polarity.

3. High-Speed Automated Feedback System

- The system immediately classifies the battery as correct or incorrect.

- Feedback is sent to the production control system, triggering sorting mechanisms or alerts.

4. Temperature and Lighting Adjustments

- Some advanced systems adjust for ambient lighting conditions to improve accuracy.

- Temperature variations that might affect image clarity are also compensated for.

Importance of CCD Polarity Testing in the Battery Industry

1. Prevents Assembly Errors

- Batteries assembled with the wrong polarity can cause short circuits, device malfunctions, or permanent damage.

- Ensuring correct polarity at the early production stage eliminates costly assembly line rework.

2. Enhances Safety

- Misoriented batteries can lead to fire hazards, explosions, or system failures.

- Particularly crucial for high-energy applications like EVs, medical devices, and energy storage solutions.

3. Improves Production Efficiency

- Automated CCD testers reduce manual inspection time, improving throughput.

- Early error detection minimizes waste and rework costs.

4. Ensures Compliance with Industry Standards

- Battery manufacturers must adhere to safety and quality regulations such as ISO, IEC, and UL standards.

- Automated polarity testing ensures compliance without human error.

5. Reduces Costs and Defective Product Returns

- Incorrectly oriented batteries reaching the market can lead to warranty claims, recalls, and reputational damage.

- CCD polarity testers prevent such failures, saving millions in potential losses.

Applications of CCD Polarity Tester Machines

1. Electric Vehicle (EV) Battery Production

- Ensures correct orientation of high-voltage battery cells and modules before pack assembly.

- Reduces the risk of electrical failure in EV power systems.

2. Consumer Electronics Manufacturing

- Used in battery production for smartphones, laptops, and wearable devices.

- Prevents polarity-related malfunctions in sensitive electronic devices.

3. Energy Storage Systems (ESS)

- Large-scale battery storage requires precisely matched cells.

- CCD testers ensure proper polarity before battery module integration.

4. Aerospace and Défense Batteries

- In critical applications, such as satellites and military equipment, battery failures are unacceptable.

- CCD testers provide high-precision verification for safety-critical batteries.

Choosing the Right CCD Polarity Tester for Your Needs

When selecting a CCD Polarity Tester, manufacturers should consider:

1. Accuracy and Resolution

- High millivolt precision ensures reliable results.

- Look for CCD cameras with high pixel resolution for better image clarity.

2. Speed and Automation Level

- Automated testers are essential for high-volume battery production.

- Look for systems with integrated robotic handling for increased efficiency.

3. Software Integration and AI Capabilities

- Advanced systems use AI-powered image recognition to improve accuracy.

- Machines that integrate with manufacturing execution systems (MES) enable real-time monitoring.

4. Compatibility with Different Battery Types

- The machine should support cylindrical, prismatic, and pouch cells.

- Should be adaptable to multiple battery chemistries, including Li-ion, NiMH, and LFP.

5. Temperature and Environmental Adaptability

- Choose a tester with adjustable lighting and temperature compensation for reliable readings in different factory environments.

Conclusion

A CCD Polarity Tester Machine is a critical tool in battery manufacturing, ensuring that battery terminals are correctly oriented before further processing. By using high-precision imaging, automation, and AI-based vision systems, these machines eliminate polarity errors, enhance product reliability, and improve overall manufacturing efficiency.

In industries such as EVs, energy storage, and consumer electronics, CCD polarity testing plays a key role in ensuring safety, compliance, and product longevity. As battery technology advances, the demand for high-speed, accurate, and automated polarity testing solutions will continue to grow.